Image source: Takisawa Taiwan

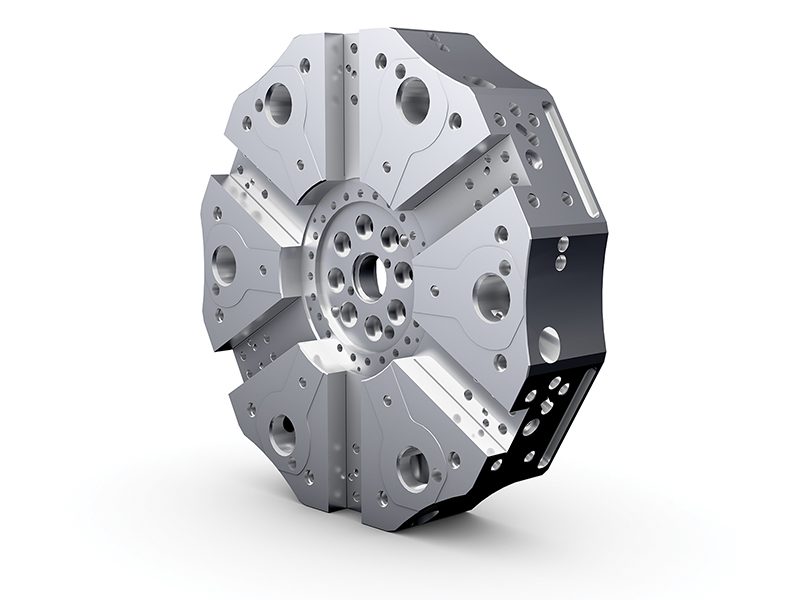

A turret is a device mounted on a lathe that holds multiple cutting tools. These turrets rotate and index the tools, allowing for automatic tool changes during machining operations. This eliminates the need for manual tool changes, saving valuable time and improving overall efficiency.

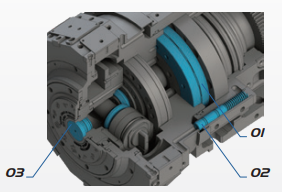

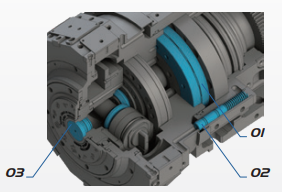

A turret consists of several parts including main body, tool holder, turning stick, curvic coupling and index motor.

Image source: Takisawa Taiwan

01: Curvic coupling 02: High-pressure coolant 03: Grease supply

Image source: Takisawa Taiwan

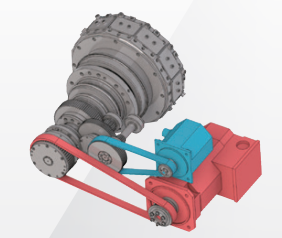

The BMT turret, or Base Mount Turret, is known for its exceptional rigidity and robust construction. It provides increased stability during heavy-duty machining operations. One of the key advantages of the BMT turret is its enhanced tooling capacity. It can accommodate a larger number of tools compared to other turret types, allowing for a wider range of machining options without the need for frequent tool changes.

The BMT turret employs a wedge locking mechanism to ensure secure tool clamping, minimizing tool vibrations and improving machining precision. Additionally, the BMT design provides excellent radial and axial tool stiffness, enabling efficient metal removal rates. This makes it an ideal choice for applications that demand high rigidity, such as heavy turning, milling, and complex contouring operations.

The VDI turret, also known as the Verein Deutscher Ingenieure Turret, is a widely used tooling system in CNC machining. It offers exceptional versatility and quick tool changes, making it suitable for various machining requirements. The VDI turret follows a standardized interface that allows for easy interchangeability of tools between different lathe machines.

One of the key features of the VDI turret is its radial drive system, which enables fast and reliable tool indexing. This system ensures precise positioning of tools, reducing setup times and maximizing productivity. The VDI turret can accommodate a wide range of tool sizes and types, including turning tools, boring bars, drills, and even live tooling for milling operations. This flexibility makes it a popular choice for job shops and manufacturing facilities with diverse machining needs.

VDI TOOLHOLDER SERIES & COMPATIBLE LATHES

| VDI40 | 6"/8"/10"/12"/15"/18" lathes |

The BOT turret, or Bolt-On Turret, provides a cost-effective tooling solution for CNC lathes. The turrets accept bolt-on toolholders around the perimeter, and have radial slots on the face for mounting turning tools in either the right- or left-hand direction. This turret offers simplicity and ease of installation. The BOT turret is designed to hold a limited number of tools but provides reliable performance for specific machining applications.

This Bolt-On Tool Turret accepts 1" (25 mm) or other size of turning sticks on the face, and uses bolt-on toolholders (80 mm x 45 mm bolt pattern, or other types) around the turret OD.The BOT turret is commonly used for small to medium-sized lathes and is ideal for low to medium complexity turning operations. It offers good tool accessibility, making it suitable for applications where a few frequently used tools are sufficient. Although it may not have the tooling capacity of the BMT or the versatility of the VDI turret, the BOT turret serves as a practical and budget-friendly option for certain machining requirements.

BOT TOOLHOLDER SERIES & COMPATIBLE LATHES

| BOT10 | 6" lathes |

| BOT20 | 8"/10"/12" lathes |

| BOT40 | 15"/18"/21"/24" lathes |

| BOT50 | 15"/18"/21"/24" lathes |

HAAS这款 12 刀位混合 BOT/VDI 刀塔(6 VDI40 和 6 BOT)在端面容纳 VDI40 刀柄和 1.25" (32 毫米) 车刀杆,在刀塔外径使用工业标准的螺栓紧固刀座(105 毫米 x 70 毫米 螺栓样式)。

HAAS's 12 position hybrid BOT/VDI turret (6 VDI40 and 6 BOT) accommodates the VDI40 tool holder and 1.25 "(32mm) turning stick on the face. The turret is tightened with industry standard bolts (105mm x 70mm bolt style) on the outer surface of the turret.

HYBRID TOOLHOLDER SERIES & COMPATIBLE LATHES

| BOT10 VDI40 | 6"/8" lathes |

| BOT20 VDI40 | 8"/10"/12" lathes |

| BOT40 VDI40 | 15"/18" lathes |

Each type of CNC tool turret has its strengths and is best suited for specific applications. Let’s compare the BMT, VDI, and BOT turrets based on various factors:

| Turret Type | Tooling Capacity | Rigidity | Versatility | Cost-effectiveness |

| BMT | High | Excellent | Moderate | Moderate |

| VDI | Moderate | Good | High | High |

| BOT | Low | Moderate | Low | Excellent |

When selecting a CNC tool turret for your machining operations, several factors should be taken into account:

Machining requirements: Consider the complexity, precision, and volume of the machining tasks you regularly perform.

Tool variety: Assess the range of tool types and sizes needed for your applications.

Rigidity and stability: Determine if your machining processes require high rigidity for optimal results.

Cost considerations: Evaluate your budget and choose a turret that offers the best balance between cost and performance.

Future scalability: Consider your future machining needs and select a turret that allows for easy expansion or tooling modifications.

CNC tool turrets find applications in various industries that rely on precision machining. Some common applications include:

Aerospace: Manufacturing components like turbine blades, landing gears, and engine parts.

Automotive: Producing engine components, transmission parts, and steering system elements.

Medical: Fabricating implants, surgical instruments, and medical device components.

Energy: Machining parts for turbines, generators, and oil and gas equipment.

General manufacturing: Supporting a wide range of machining tasks, from simple to complex operations.

CNC tool turrets are indispensable components of modern machining processes. The BMT, VDI, and BOT turrets are three common types, each offering unique features and advantages. The BMT turret excels in rigidity and tooling capacity, while the VDI turret provides versatility and quick tool changes. The BOT turret serves as a cost-effective option for specific machining requirements. By understanding the strengths and applications of these turrets, you can make informed decisions to optimize their machining operations and achieve desired results.